TCM Turnkey Projects – The Supreme Discipline of the TCM Engineering Team

“Tools ordered, processes optimized – and still no stable series production?” In many cases, the issue isn't the tool itself, but the lack of overall process coordination. This is exactly where TCM’s turnkey concept comes into play.

Experience That Delivers Results

For many years, TCM has been designing and producing custom tools for specialized machining tasks—with one clear goal: to sustainably increase our customers’ productivity.

Especially for the initial production of new parts, TCM was often entrusted with the complete tool concept. The tools delivered were successfully put into operation at the customer site as a turnkey package.

And it’s not just new parts that benefit: existing series production has also been made significantly more efficient through targeted re-tooling projects.

Systematic Expansion of Expertise

Thanks to a wide range of implemented projects and continuous tool testing in our tool management programs, TCM has gained extensive practical experience.

Based on this, we expanded our service portfolio in 2024 to include:

- CAM programming of parts

- Design and procurement of customized clamping fixtures

A logical step—and a real added value for our customers.

Why Turnkey? – The Challenges of Past Projects

In the past, collaboration with CNC programming and workholding often proved time-consuming and error-prone:

- Lack of coordination with on-site CNC programming

- Poorly designed clamping fixtures

- Long project lead times (4–6 months)

- Incomplete or missing documentation

- Handover of processes that were not ready for series production

The TCM Turnkey Approach – Everything from a Single Source

A turnkey project with TCM simplifies and accelerates your processes.

Starting from your machine tool and project requirements (cycle time, quality criteria, part drawings, etc.), TCM handles every subsequent project step:

Our Services at a Glance

- Selection of optimal machining strategies

- Design and compilation of all tools and toolholders

- Customized clamping fixture concepts for your specific machine

- Digitalization of all tool data (including WINTOOL datasets)

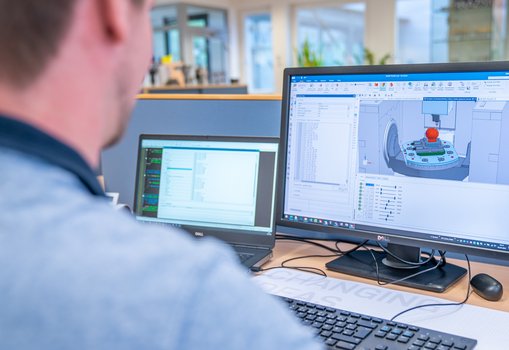

- CAM programming using Siemens NX

- Collision check and tool length optimization

- Procurement, assembly, and presetting of all components

- On-site machine setup and tool commissioning – until the first OK part is produced

Even after the project launch, continuous optimization is carried out in close collaboration with your team.

Record-Breaking Project Lead Times

Thanks to seamless collaboration between our technical departments, we typically achieve project lead times of just 8 to 10 weeks—from the initial startup meeting to the first production-ready part.

✅ Your Benefits at a Glance

| Advantage | Description |

|---|---|

| Everything from a single source | Tools, CNC program, and clamping solution – one point of contact |

| Short project lead times | Speed through streamlined processes |

| Predictable costs | Transparency and planning reliability |

| Guaranteed performance metrics | Productivity through defined goals: – Tool costs (CPU) – Cycle time |

| Digital component mapping | Simulation-ready and future-proof |

| Long-standing experience | Top quality through technical expertise |

| On-site support | Process reliability directly in your production environment |

| Comprehensive documentation | Full traceability and completeness |

We’ll Show You How to Integrate Tools, Programming, and Workholding into One System – Quickly, Efficiently, and Reliably.

👉 Contact us now to learn more about turnkey projects with TCM.

With more than 40 years of broad cutting experience, TCM is an attractive technology partner.

oscheibenbauer@tcm-international.com

Start-up meeting – Definition of the machining strategy

CAM programming of the components

Tool design and preparation of digital tool data

Mechanically operated fixture

Hydraulically operated fixture