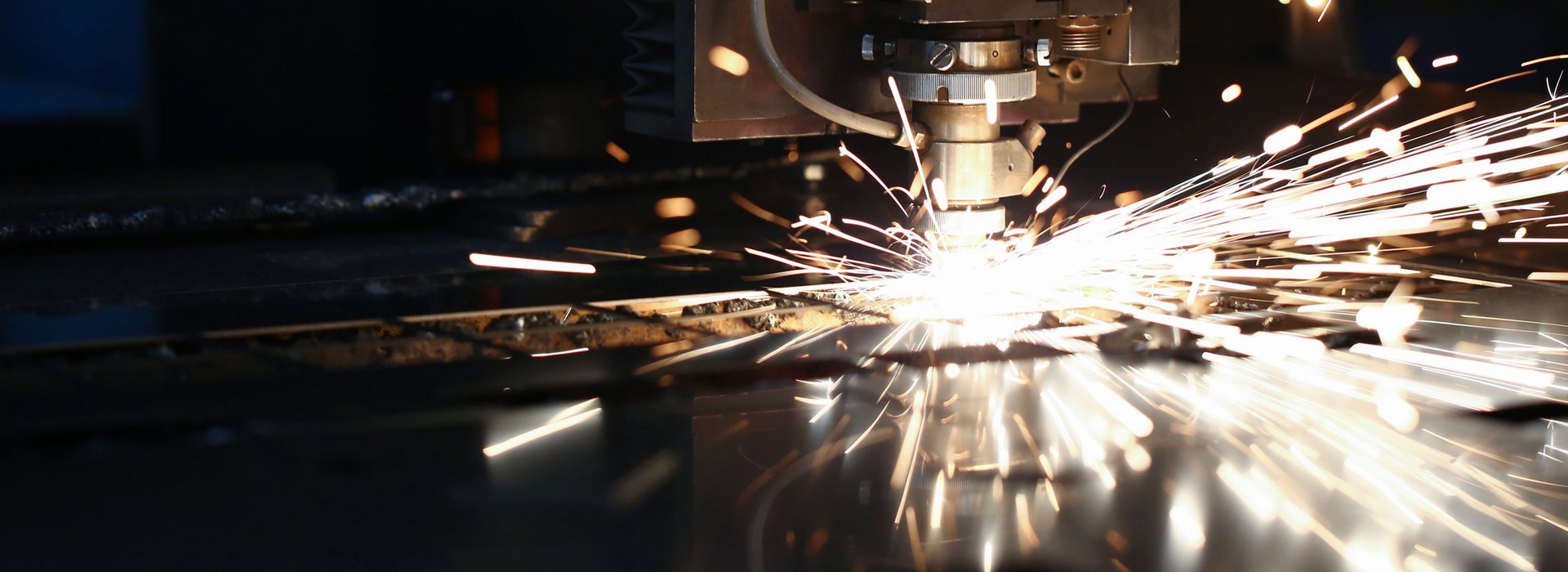

Lean set-up - reliable processes through transparency and integration

With the organization of lean and flexible work processes, WinTool increases the productivity of a company while also reducing set-up times and operating costs. For almost 40 years, WinTool AG has been developing software solutions for successful completion of CNC production. Maybe soon for your business?

Since 1980, WinTool AG has been developing a smart and easy-to-use tool and data management system in cooperation with various high-end machining companies. WinTool AG is a specialized company that develops, distributes and supports software solutions for the efficient organization of CNC production. The company, based in Switzerland, offers the only independent and neutral solution in the CNC periphery.

Thinking Management System

With WinTool, tools that are needed for a production order are delivered reliably and punctually to the machine. As a result, the long set-up times are reduced, while the flexibility of planning and the capacities increase. WinTool manages all tools in the warehouse as well as in the production plant and knows how and, above all, where the equipment is planned and used. The software proposes the optimal setup process, which is possible from the available tools, detects bottlenecks and also looks for alternative setups. The employees in the tool center and on the machine can do their work efficiently and without hassle.

This is what WinTool can do

The software always supplies the correct tools to the machines, which not only identifies bottlenecks in the resources, but corrects them immediately. Even the tool stores are managed quickly and regularly, which avoids the emergence of bottlenecks. Another advantage of WinTool is enjoyed by the tool providers whose work is made simpler and more efficient by the software. This happens because WinTool removes the non-value-added work from the machine. Thanks to the good overview in the software, employees from the areas of programming, tool dispensing and production can work hand in hand without encountering any ambiguity as the information of the resources is displayed transparently.

Sole leader

WinTool AG was founded in 1980 by the Swiss Walter Götschi as the software house "DATOS Computer AG". From the very beginning, WinTool has been active in the metal-cutting industry and has made a name for itself worldwide with workshop-oriented software solutions in various industries. Since specializing in the "WinTool" process solution, more and more customers, including small and medium-sized companies as well as large corporations, are using WinTool as an integrated tool to achieve maximum efficiency across the entire process chain - from order to finished part. As an independent company, WinTool is not limited in its collaboration with companies, the partnership with the leading manufacturers in the entire CNC periphery makes it possible to offer users an integrated solution with continuous data from the digitized tool to the actual generated chip in the machine. The result is the leading system solution for manufacturing data and tool management, which impresses with its flexibility and simplicity, directly impacting increased productivity in manufacturing.

BR Roger Ineichen

The software always supplies the correct tools to the machines, which not only detects bottlenecks in the equipment, but also remedies them as quickly as possible.

roger.ineichen@wintool.com