Reclassification of TCM Technology Projects:

For the permanent optimization of machining processes and the most desired reduction in production times, the TCM tool experts team is permanently working in cooperation with customers and machine and tool suppliers on technical projects, in order to achieve the production goals and quantities defined by the customer.

Due to the various tasks that our customers have brought to the technical team over time, it has now become necessary to redefine the technology projects in cooperation with the TCM QM department. The individual, necessary process steps and the TCM employees responsible for them have been precisely determined in order to guarantee the smooth and punctual project process for our customers

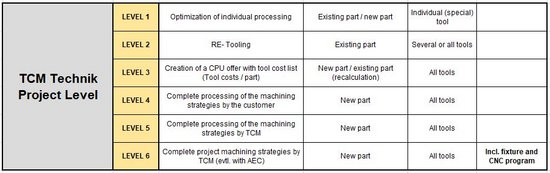

As in the Tool Management area, the TCM technology projects have been divided into 6 levels.

Taking into consideration the scope of the project specified by the customer and the project management required by TCM for processing, the individual project levels have been redefined according to the following list:

TCM Technology Project Level 1 – 6: (Link to the picture)

The first steps in every technical project are the precise coordination of the scope of the project at a start-up meeting at the customer's site.

The customer must provide all the technical data relevant for processing.

This primarily concerns raw and finished part drawings, material, 3D models, machine data, required processing time and quality features, as well as the lot size to be produced and the project time available until the production of the first parts (SOP).

After creating the processing proposal and approval by the customer, the offer is made.

The TCM offer includes the prices of all tools and tool holders required for machining, the costs for equipment and programming (level 6) and, if applicable, the daily rates / travel expenses of the TCM tool experts for implementation at the customer.

After the order has been placed by the customer, the manufacture and procurement of the tools, tool holders and devices, as well as the CNC programming, are tackled.

Also, the digital 3D tool data for CAM programming, as well as the setting plans for tool assembly are designed and provided.

A Technology Project Level 6 is a special challenge for us.

After the precise definition of the processing steps and construction of the tools, the design of the clamping device is the next step, whereby the clamping points on the part are determined together with the customer.

In addition to the stability, functionality and accessibility of the device, the interface with the machine table or the range of machines used by the customer must also be examined and discussed in detail.

For the programming of the part, the next steps are the procurement of the suitable postprocessor and the transfer of the digital model of the processing machine with the available work space and the maximum possible travel paths of the machine axes.

Finally, the accessibility and positioning of the tools relative to the individual machining points are checked during the collision test.

If there is a collision with the clamping device in the digital simulation, the tools or the clamping device are adjusted accordingly.

Possible modifications:

Tool :

Extension of the tool or tool holder

Modification of the basic tool body (e.g. neck clearance)

Machining from the opposite side

Change in the machining strategy

Threading and unthreading with a tool behind the interference contour

Fixture :

Change in the position of the clamping elements and any supply lines

Larger milling of partial runs or piercings

Position the parts differently (at an angle) on the device

Intelligent arrangement of the parts on a clamping tower or pyramid

During the commissioning of the tools and the production of the first parts, TCM tool experts accompany you on site at the machine and optimize the cutting values until the desired machining results and cycle times are achieved.

With more than 40 years of broad cutting experience, TCM is an attractive technology partner.

oscheibenbauer@tcm-international.com