3 becomes 1! Productivity advantages through step drills:

Since solid carbide drills for machining steel materials have been available on the market, the engineering department at TCM has continuously designed, manufactured and developed solid carbide step drills for efficient use in serial production.

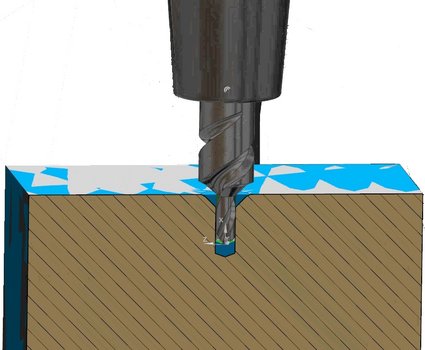

The main task of step drilling tools is, to combine several drilling and chamfering operations in only one tool, which can drastically reduce machining time.

The development of step drills with one to two steps and additional chamfering of all manufactured holes have always been our daily business. Special attention must be paid due to the cutting geometry primarily to the material to be machined. With short-chipping materials such as grey cast irons or aluminum die castings, more diameter steps and profile contours can easily be realized, due to the short chips. The situation is different when drilling steel materials, where long chips are usually produced by the step cutting edges during drilling, which wrap themselves around the drill and the tool holder and can thus severely disrupt series production. In addition, these long chips often leads to a jam of chip in the flutes of step drills.

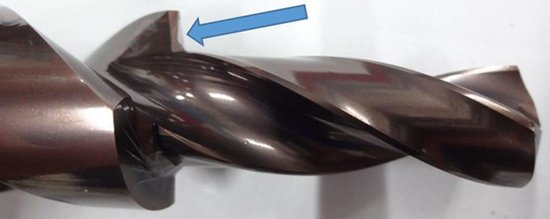

This effect can be prevented by a special tool design, so-called correction grinding. In this process, the sharp step cutting edges, which result from the 30° spiral angle of the flutes, are corrected due to the tool center line. The correction angle and the width of the correction grinding, can be specified in the CNC grinding program. If the correction grinding is applied neutrally, i.e. exactly on the center line, the rake angle of the stepped flutes changes from +25 ° to 0°. As a result, the chips cannot slide backwards as long chips from the otherwise extremely sharp step cutting edges, but are compressed by the 0° rake angle, which causes the chips to curl and break. This effect can be further enhanced by positive or negative correction angles. The resulting small chip curls, can then be easily removed by the help of the inner coolant.

Solid carbide step drills are manufactured from carbide rods with internal cooling channels produced by carbide manufacturers. Due to the different diameters of the step drill tools, the suitable cooling channel rod must first be selected when designing a step drill. For this purpose, there are various designs of the blanks with different cooling channel diameters and center distances of the cooling channels.

If large diameter differences have to be combined in one tool, then it even may be necessary, to order special carbide blanks.

Read more about the realization of an optimization project:

With more than 40 years of broad cutting experience, TCM is an attractive technology partner.

oscheibenbauer@tcm-international.com

Axial correction grinding on the step

Solid carbide cooling channel blanks